Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

Professional stamping parts factory, metal stamping parts factory, stamping part factory. Different tons of punching machines from 15T to 2000T can meet the production of any kinds metal stamping parts. IATF 16949 certified and Advanced testing equipments make us to ensure high quality products.

factory provide metal stamping fabrication, metal stamping and fabrication,progressive stamping and fabrication, metal forming stamping,metal stamping bending. progressive die completes all the forming processes of the product in one die, which overcomes the operation invariance and cumulative error caused by multiple positioning when using a simple die

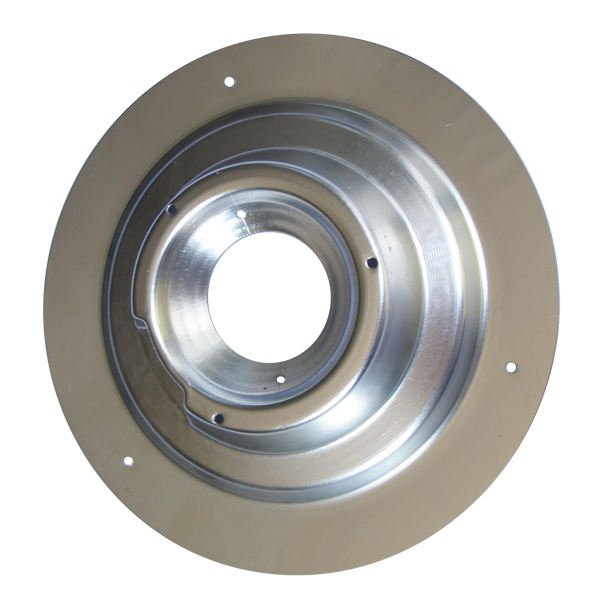

Sheet Metal Deep Drawing Stamping

Deep drawing is a manufacturing process used to shape sheet metal into complex, hollow parts. This technique is common in the automotive, aerospace, and consumer goods industries.

Sheet metal deep drawing stamping is a manufacturing process used to form sheet metal into three-dimensional shapes, typically cylindrical or box-like structures with depth greater than their diameter or width. This process involves placing a flat sheet of metal, often referred to as a blank, over a die and then using a punch to force the metal into the die cavity. The metal is drawn into the die cavity under high pressure, causing it to conform to the shape of the die.

Blank Preparation: The process starts with the preparation of the flat sheet metal blank. The blank is usually cut from a larger sheet to the required size and shape.

Placement on Die: The blank is placed over a die, which is a tooling component with a cavity that matches the desired shape of the final part.

Application of Force: A punch, which is another tooling component, is brought down onto the blank with significant force. This force causes the blank to be drawn into the die cavity.The process is to draw sheet metal.

Material Flow: As the punch applies force, the metal blank undergoes plastic deformation and flows into the die cavity, taking on the shape of the die,that is drawing stamping.

Friction and Lubrication: Friction between the metal and the die can be significant and can affect the forming process. Lubricants are often used to reduce friction and improve the flow of the metal.

Forming Limits: The forming process must be carefully controlled to avoid defects such as wrinkling, tearing, or thinning of the metal beyond acceptable limits.

Trimming and Finishing: After the forming process is complete, any excess material (flash) is trimmed off, and the part may undergo additional finishing operations such as deburring or surface treatment.

Sheet metal deep drawing stamping is commonly used in the automotive, aerospace, appliance, and electronics industries to manufacture a wide range of components, including automotive body panels, kitchen sinks, metal enclosures, and electronic device housings. It offers advantages such as high production rates, low per-part costs, and the ability to produce complex shapes with tight tolerances.

Our factory has a complete deep draw stamping production line. We can provide you with a one-stop customized deep drawing sheet metal.