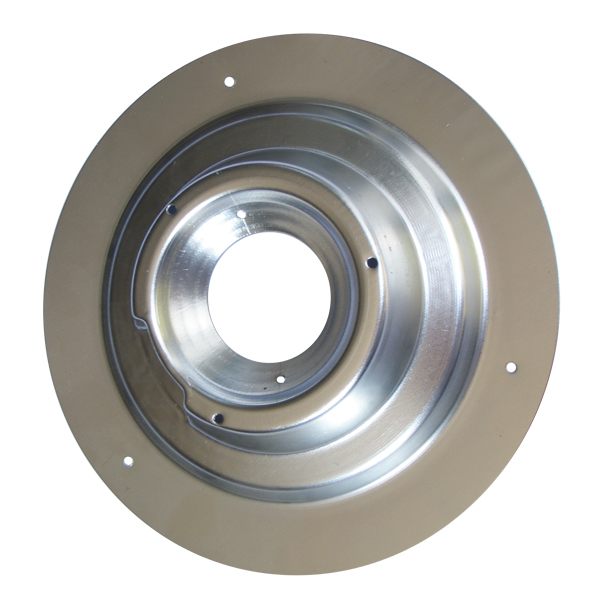

Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

CNC bend factory provide cnc metal tube bending service CNC bending factory made in China Our factory provide cnc tube bending service CNC bending service available CNC Bend OEM Best quality cnc metal bending

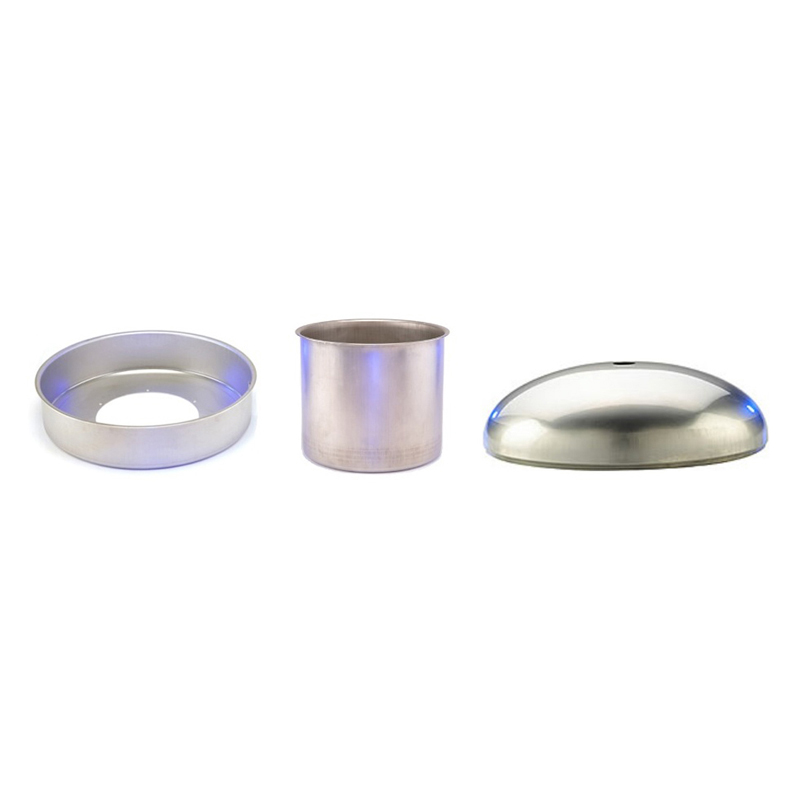

Provide OEM ODM service for metal stamping,stainless steel stamping. Our factory has over 25 years of experience in precision sheet metal stamping. High volume metal stamping with factory price. High precision metal stamping made in China.

Progressive Metal Bending Forming Stamping And Fabrication

Metal Stamping: This is the process of shaping metals using a die and a punch. The metal sheet is placed between the die (which has a cavity) and the punch (which applies force). The force exerted by the punch causes the metal to deform into the shape of the die.

Bending: In the context of metal stamping, bending specifically refers to the deformation of the metal sheet to create angles, curves, or shapes that are not flat. Bending typically occurs when the metal is forced into a V-shaped or U-shaped die, which causes it to curve or fold.

Equipment: Metal stamping and bending are usually carried out using specialized equipment such as presses, which apply the necessary force to deform the metal. Dies are crucial components as they determine the final shape of the bent metal.

Applications: Metal stamping bending is used in various industries including automotive, aerospace, electronics, and manufacturing. It is employed to create components such as brackets, panels, enclosures, and structural elements that require precise shapes and angles.

metal stamping fabrication, metal stamping and fabrication,progressive stamping and fabrication, metal forming stamping,metal stamping bending.

Metal Stamping and Fabrication are two closely related manufacturing processes used to shape, cut, and assemble metal parts.

Metal Stamping Fabrication is a manufacturing process used to convert flat metal sheets into specific shapes using a stamping press. It is widely used in various industries, including automotive, aerospace, electronics, and appliance manufacturing.

Overall, metal stamping bending is a versatile manufacturing process that allows for the production of complex metal components efficiently and with high precision, making it essential in modern industrial manufacturing.