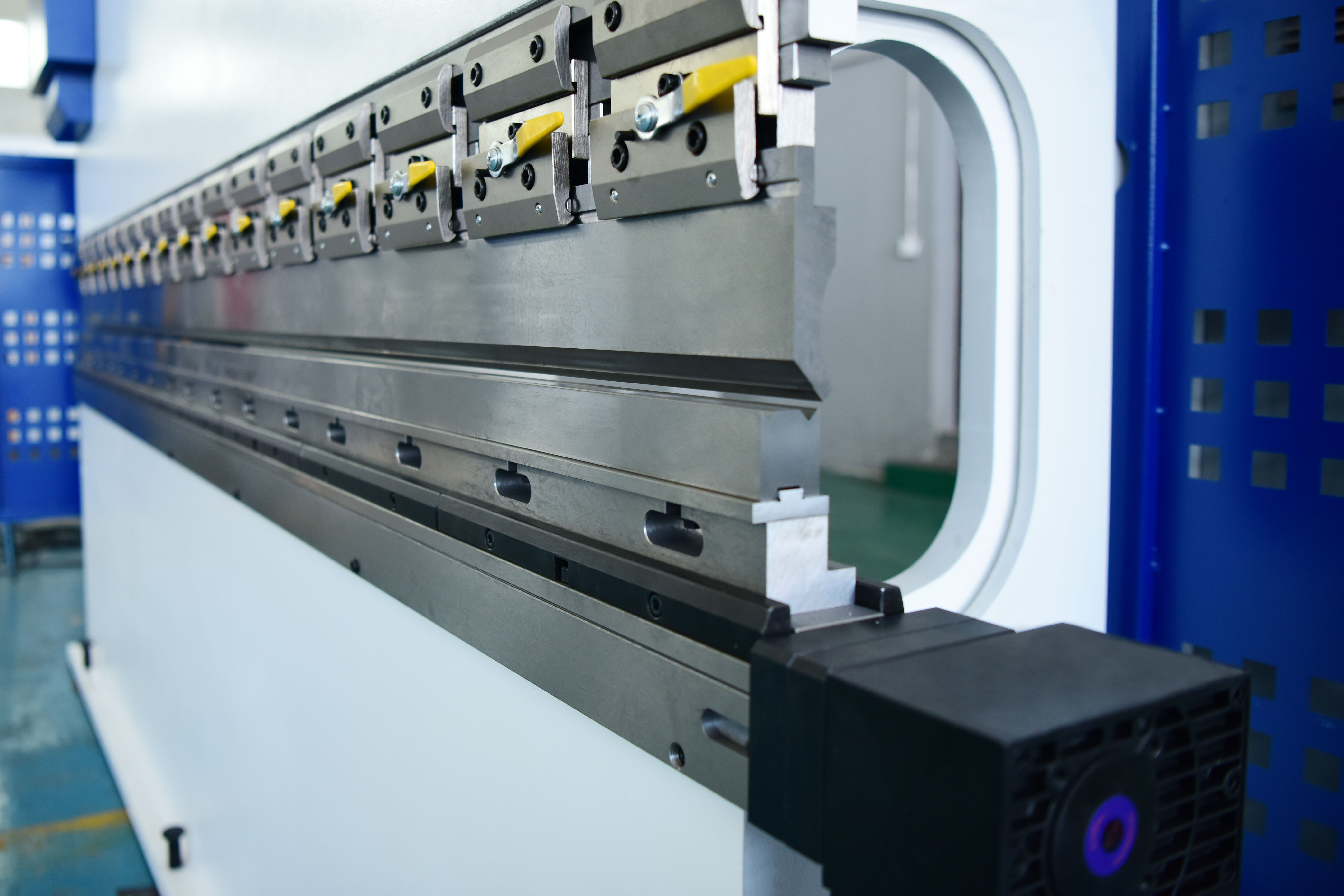

CNC bending is a high-precision metal processing technology widely used in the forming process of metal sheets. This technology precisely controls the movement and pressure of the bending machine through a computer numerical control system to achieve complex bending shapes and angles.

With the continuous advancement of technology, CNC bending machines will continue to bring more innovation and breakthroughs to the manufacturing industry, driving the sustained development and progress of the entire industry.

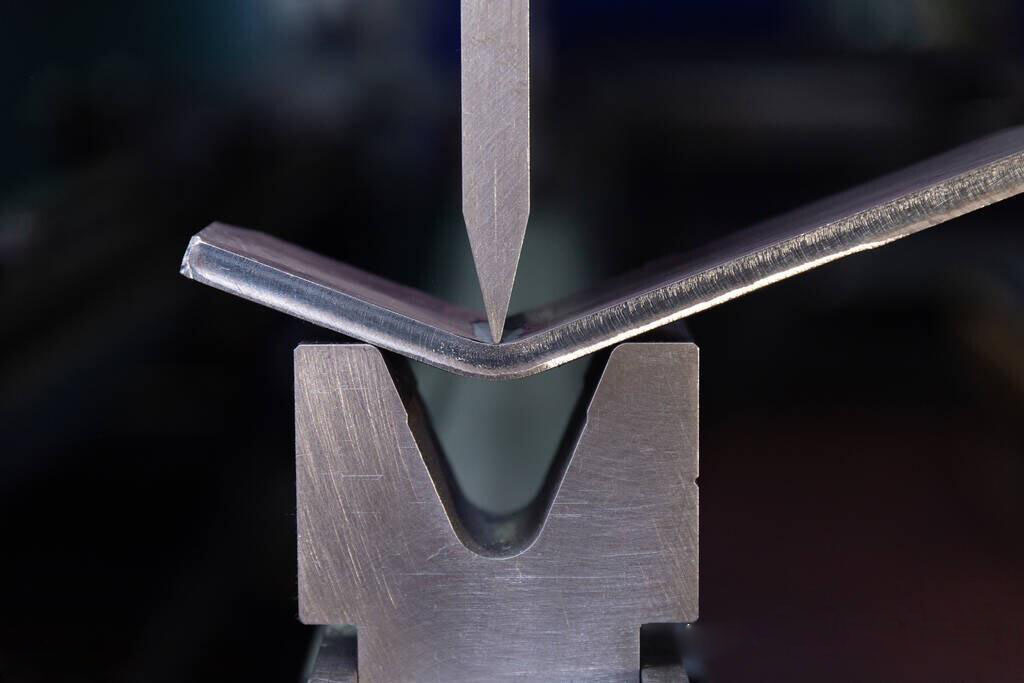

CNC bending is the precise bending of cold metal sheets into various geometric cross-sectional shapes using CNC machining equipment.

The CNC bending equipment inputs the required bending angle, bending position and other process parameters through computer programming, and controls the hydraulic system or motor to drive the bending mold to accurately bend the metal sheet.

It is a sheet metal forming machine designed for cold rolling sheet metal processing, widely used in sheet metal bending processing in industries such as automobiles, aircraft manufacturing, light industry, shipbuilding, containers, elevators, and railway vehicles.

CNC bending has become one of the important methods for modern metal sheet metal processing due to its high efficiency, precision, and good repeatability.