Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

Professional stamping parts factory, metal stamping parts factory, stamping part factory. Different tons of punching machines from 15T to 2000T can meet the production of any kinds metal stamping parts. IATF 16949 certified and Advanced testing equipments make us to ensure high quality products.

factory provide metal stamping fabrication, metal stamping and fabrication,progressive stamping and fabrication, metal forming stamping,metal stamping bending. progressive die completes all the forming processes of the product in one die, which overcomes the operation invariance and cumulative error caused by multiple positioning when using a simple die

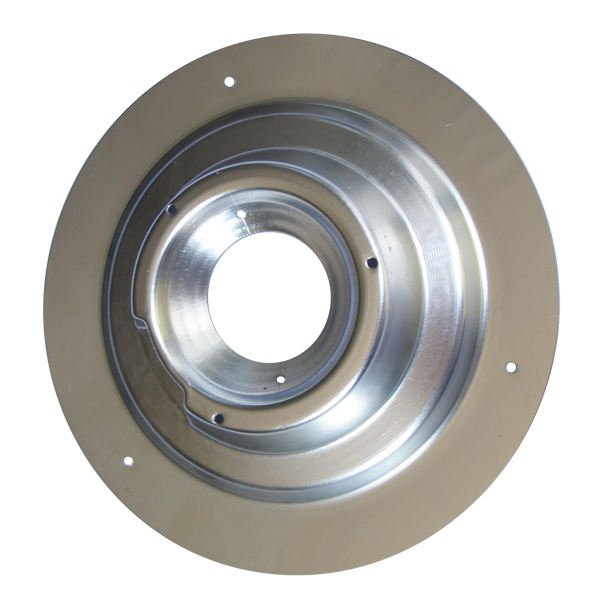

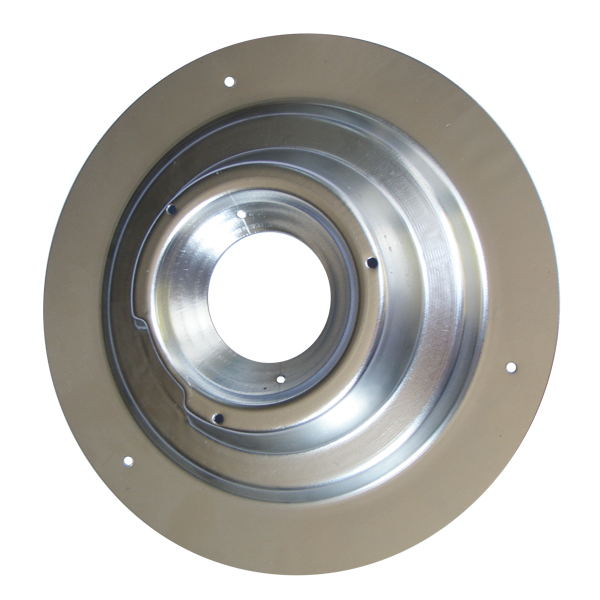

Metal Stamping Parts Factory

Metal stamping parts are components manufactured through the process of metal stamping, which involves pressing or punching a metal sheet or coil with a mechanical or hydraulic press to create the desired shape. This process is widely used in various industries due to its ability to produce parts with high precision and repeatability at a relatively low cost.

Key words:stamping parts factory, metal stamping parts factory, stamping part factory.

Processes: The process typically involves several stages:

- Blanking: Cutting the rough outline of the part from a metal sheet.

- Piercing: Creating holes or other features in the part.

- Forming: Bending or shaping the metal to achieve the final geometry.

- Drawing: Forming deep or complex parts by pulling the metal through a die.

- Coining: Precision stamping to achieve tight tolerances or smooth surfaces.

Tooling: Metal stamping requires specialized tooling, including dies and punches, which are designed based on the part's geometry and material thickness. Tooling costs can be significant but are amortized over large production runs.

Materials: Metal stamping can be performed on a variety of metals, including steel, aluminum, copper, and alloys like brass and bronze. The choice of material depends on the specific requirements of the part in terms of strength, conductivity, corrosion resistance, etc.

Applications: Metal stamping parts are used in various industries such as automotive (brackets, panels), aerospace (structural components), electronics (connectors), and appliances (cabinets, enclosures).

Quality Control: Inspection and quality assurance processes are crucial to ensure parts meet specifications. Techniques include visual inspection, dimensional measurement, and material testing.

Advantages:

- Cost-effective: High-speed production lowers per-unit costs.

- Precision: Tight tolerances can be achieved, ensuring consistency in part dimensions.

- Complexity: Capable of producing complex geometries that may be difficult or costly with other manufacturing methods.

Overall, metal stamping is a versatile manufacturing process that plays a crucial role in producing a wide range of metal parts used in everyday products and industrial applications.

We are metal stamping parts factory with 25years experience,please send us your design drawings.

We will give you best price and high quality service.