Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

Professional stamping parts factory, metal stamping parts factory, stamping part factory. Different tons of punching machines from 15T to 2000T can meet the production of any kinds metal stamping parts. IATF 16949 certified and Advanced testing equipments make us to ensure high quality products.

factory provide metal stamping fabrication, metal stamping and fabrication,progressive stamping and fabrication, metal forming stamping,metal stamping bending. progressive die completes all the forming processes of the product in one die, which overcomes the operation invariance and cumulative error caused by multiple positioning when using a simple die

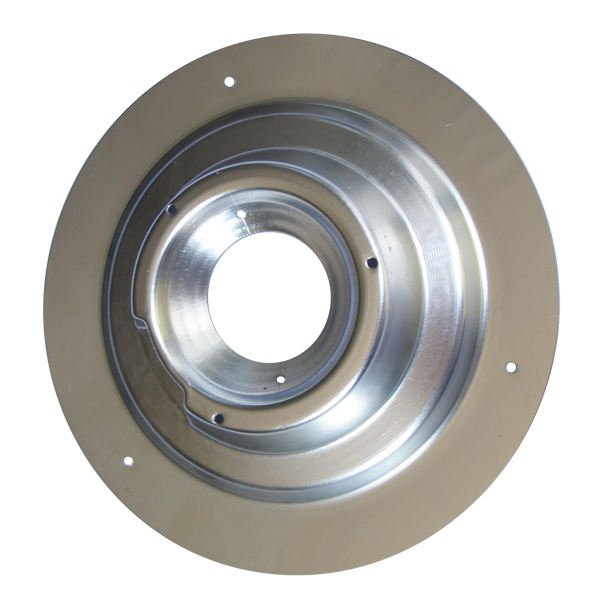

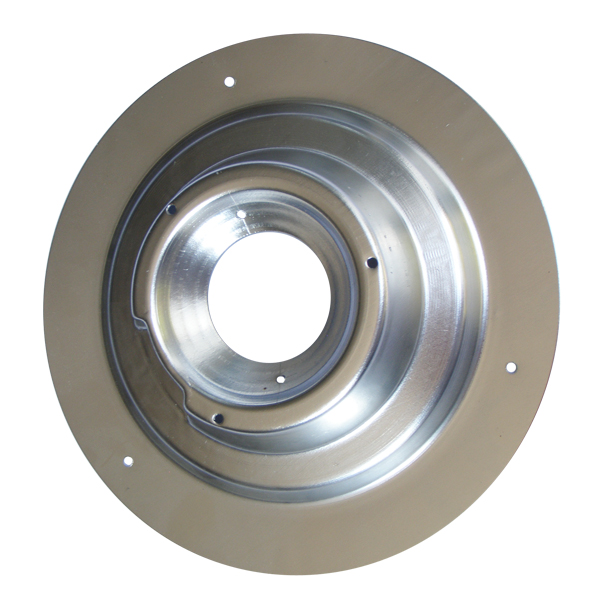

Precision Metal Titanium Aluminum Sheet Stamping

Precision metal stamping is a manufacturing process used to create parts and components from sheet metal. It involves feeding flat sheet metal into a stamping press where a tool and die set forms the metal into the desired shape. This process is highly automated and precise, capable of producing complex geometries with tight tolerances. Precision metal stamping includes but is not limited to aluminum stamping, stamping aluminum sheet, titanium stamping.

Tool and Die: The tool and die set consists of a punch (which pushes the metal into the die), the die (which shapes the metal), and possibly other components like strippers and holders.

Materials: Typically uses sheet metal materials such as steel, aluminum, brass, copper, and sometimes exotic metals depending on the application's requirements.

Precision and Tolerances: Offers high precision and repeatability, making it suitable for mass production of parts with tight tolerances.

Automation: Often automated with progressive or transfer stamping systems, reducing labor costs and increasing production efficiency.

Applications: Widely used across industries including automotive, aerospace, electronics, telecommunications, and more, where high-volume production of precise metal parts is needed.

Advantages: Provides cost-effective production of complex parts, fast cycle times, and consistency in part quality.

Overall, precision metal stamping is crucial in modern manufacturing for creating a wide range of parts that are essential in various industries due to its efficiency, precision, and capability to handle high-volume production needs.