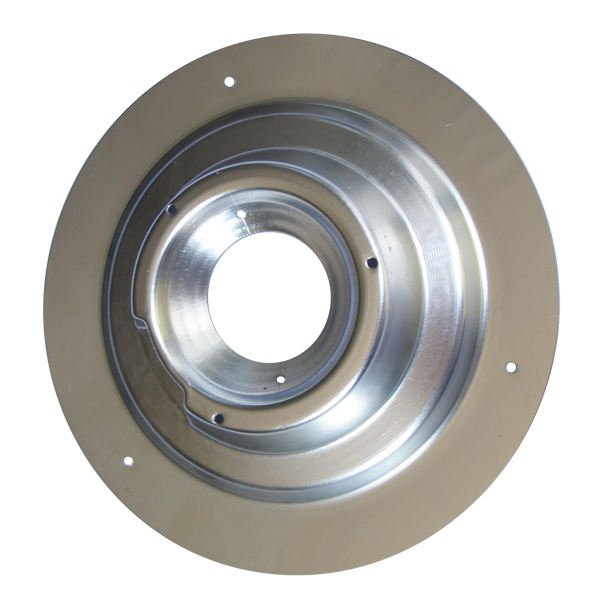

Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

Professional stamping parts factory, metal stamping parts factory, stamping part factory. Different tons of punching machines from 15T to 2000T can meet the production of any kinds metal stamping parts. IATF 16949 certified and Advanced testing equipments make us to ensure high quality products.

factory provide metal stamping fabrication, metal stamping and fabrication,progressive stamping and fabrication, metal forming stamping,metal stamping bending. progressive die completes all the forming processes of the product in one die, which overcomes the operation invariance and cumulative error caused by multiple positioning when using a simple die

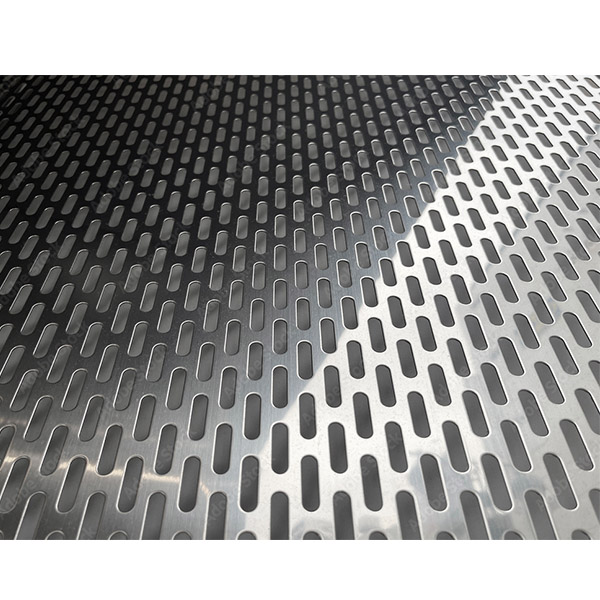

Metal Steel Plate Tag Stamping

Stamping metal steel plate tags typically involves using a specialized process to imprint information onto the surface of the metal.

Material Selection (metal tag stamping): Choose a metal that is suitable for stamping, such as stainless steel, aluminum, or brass, depending on the durability and appearance requirements.

Design Preparation: Create or obtain the design or information that needs to be stamped onto the metal tags. This could include alphanumeric characters, logos, serial numbers, or any other required information.

Stamping Equipment (metal plate stamping): Use specialized stamping equipment designed for metal tag stamping. This equipment typically includes:

- Stamping Machine: A press or a handheld stamping tool designed for metal.

- Stamping Dies(stamping steel plate): Custom dies that have the reverse of the desired design or text cut out. These are hardened steel pieces that are used to impress the design onto the metal tag.

Stamping Process:

- Alignment: Properly align the metal tag under the stamping machine or tool.

- Impression: Lower the stamp or press to apply pressure evenly across the surface of the metal tag, transferring the design onto it.

- Depth Control: Ensure the stamping depth is sufficient to create a clear, readable impression without damaging the integrity of the tag.

Finishing: After stamping, tags may undergo additional processes depending on the desired finish:

- Cleaning: Remove any debris or markings from the stamping process.

- Coating: Apply a protective coating if necessary to enhance durability or aesthetics.

Quality Control: Inspect the stamped tags to ensure the quality of the impressions meets the required standards. This may involve checking for clarity, depth, and accuracy of the stamped information.

For businesses or individuals looking to stamp metal steel plate tags, it’s often advisable to work with a specialized manufacturer or supplier who has the equipment and expertise to ensure high-quality, consistent results.