Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

Professional stamping parts factory, metal stamping parts factory, stamping part factory. Different tons of punching machines from 15T to 2000T can meet the production of any kinds metal stamping parts. IATF 16949 certified and Advanced testing equipments make us to ensure high quality products.

factory provide metal stamping fabrication, metal stamping and fabrication,progressive stamping and fabrication, metal forming stamping,metal stamping bending. progressive die completes all the forming processes of the product in one die, which overcomes the operation invariance and cumulative error caused by multiple positioning when using a simple die

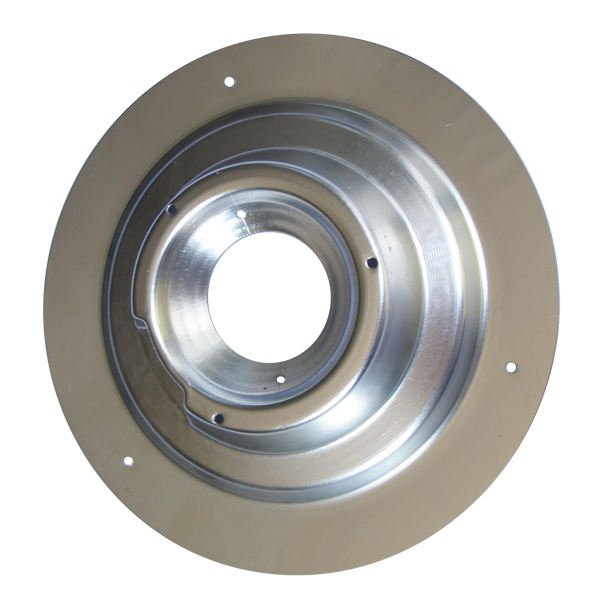

Metal Deep Draw Stamping Product

Deep draw metal stamping is a specialized process used to form sheet metal into cylindrical or box-like shapes with depths that exceed the diameter of the part.

Material Selection: The process starts with selecting the appropriate sheet metal material based on its thickness, strength, and desired properties for the final product.

Tooling Design: Tooling consists of a die (or mold) and a punch that work together to shape the metal. The die cavity is designed to gradually draw the sheet metal into the desired shape.

Blank Preparation: A flat sheet metal blank is cut to the appropriate size and shape based on the dimensions of the final part.

Drawing Process:

- The blank is placed over the die cavity.

- The punch descends and presses the sheet metal into the die cavity, causing it to form the desired shape.

- This process is usually done in multiple stages, with each stage gradually increasing the depth of the draw until the final shape is achieved.

- Lubricants are often used to reduce friction and aid in the forming process.

Trimming and Finishing: After the drawing process, excess material (called flash) may need to be trimmed off. Additional finishing operations such as deburring, cleaning, and surface treatments may also be performed to achieve the desired final product.

Key Considerations:

-Material Thickness: Thinner materials are easier to form but may require more stages to achieve deeper draws.

- Material Properties: Different metals and alloys have varying strengths and formability characteristics that affect the process.

- Tooling Design: Precision in die and punch design is critical for achieving accurate and consistent results.

- Quality Control: Monitoring dimensions, surface finish, and material properties throughout the process ensures the final parts meet specifications.

Deep draw stamping is used in various industries including automotive (for components like fuel tanks and engine parts), aerospace, electronics (for housings and components), and household appliances (for components like sinks and cookware).

Overall, deep draw metal stamping is a versatile manufacturing process capable of producing complex, seamless parts with high precision and efficiency.