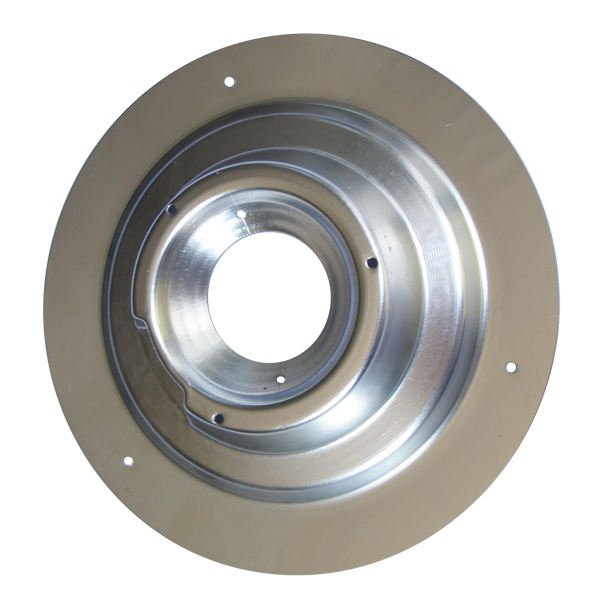

Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

Professional stamping parts factory, metal stamping parts factory, stamping part factory. Different tons of punching machines from 15T to 2000T can meet the production of any kinds metal stamping parts. IATF 16949 certified and Advanced testing equipments make us to ensure high quality products.

factory provide metal stamping fabrication, metal stamping and fabrication,progressive stamping and fabrication, metal forming stamping,metal stamping bending. progressive die completes all the forming processes of the product in one die, which overcomes the operation invariance and cumulative error caused by multiple positioning when using a simple die

Custom Progressive Die Precision Brass Copper Stamping

Precision stamping is a manufacturing process used to create high-accuracy, high-quality metal parts and components. It involves the use of dies and stamping presses to cut, shape, or form metal sheets into specific designs or patterns with exacting tolerances. This technique is often employed in industries such as automotive, aerospace, electronics, and consumer goods due to its efficiency and precision.

Design and Tooling: The process begins with designing the part and creating the necessary tooling. This includes the dies, which are custom-made to match the desired shape and dimensions of the final part. Tooling design is crucial because it dictates the accuracy and quality of the stamped parts.

Material Preparation: A metal sheet or coil, usually made from materials like steel, aluminum, or brass, is prepared for stamping. The material needs to be properly handled and fed into the stamping press to ensure consistent results.

Stamping Process: The metal sheet is fed into a stamping press, where it is placed between the upper and lower dies. The press then applies force to the dies, which cut, bend, or shape the metal according to the design. The stamping can be done in a single stroke or multiple stages, depending on the complexity of the part.

Quality Control: After stamping, the parts are inspected for quality and precision. This may involve measuring dimensions, checking for defects, and ensuring that the parts meet the required specifications.

Finishing: The stamped parts may undergo additional finishing processes, such as deburring, coating, or assembly, to meet the final product requirements.

Precision stamping including copper stamping,progressive stamping, progressive die stamping and brass stamping, is valued for its ability to produce high volumes of parts with consistent quality and tight tolerances. It’s particularly useful for creating complex geometries and detailed features that would be challenging or costly to produce with other methods.