Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

provide stamping for different material like: precision metal stamping, stamping aluminum sheet, titanium stamping. when aluminum stamping, the aluminum material is easy to produce aluminum chips during bending, which will cause point injury and indentation, So to avoid these problems, the aluminum raw material needs to be pasted with PE film and the table surface should be cleaned in time .

metal tag stamping,metal plate stamping,stamping steel plate. For many different metal tag, use steel plate to forming a shape by mould, can highly reduce processing cost and keep stable quality. deburr and break the sharp edges, zinc plated or other kinds of surfacetreatment available. stamp or laser engrave to pring some words on the plate.

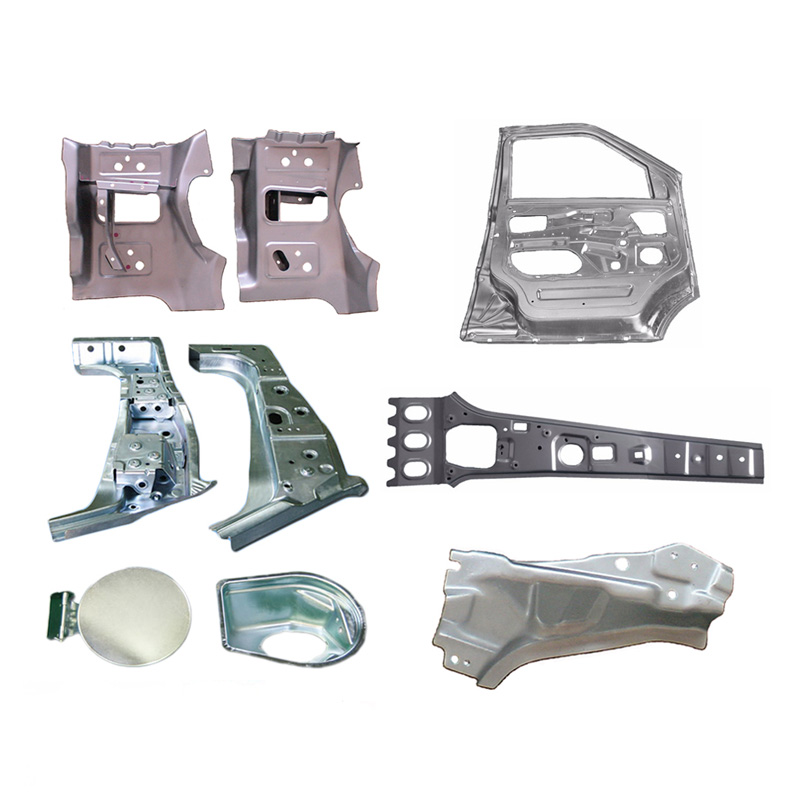

Automotive Sheet Metal Stamping Parts

Automobile body required many metal parts, most of them use stamping process to produce as it can provide lower cost, fast production and stable quality.

Key words:automotive stamping,automotive stamping parts,automotive metal stamping,stamping automotive parts,automotive sheet metal stamping.

Automotive stamping parts ,also know as stamping automotive parts refer to components of vehicles that are manufactured through a process called stamping. Stamping is a manufacturing process where flat sheet metal is pressed into a specific shape using a stamping press and dies. These parts are crucial in automobile manufacturing due to their structural integrity, precision, and ability to be mass-produced efficiently.

Stamping/Pressing: The metal sheets are fed into a stamping press, where they are pressed between the dies to form the desired shape. This can involve several stages, including blanking (cutting out the rough shape), forming (shaping the metal), and trimming.

Body Panels: Stamping is used to create parts like doors, hoods, and fenders.

Structural Components: It includes parts like cross-members and reinforcement panels that contribute to the vehicle’s structural integrity.

Engine Components: Some engine parts, like valve covers or oil pans, are also stamped.

Precision and Consistency: Stamping produces parts with high accuracy and repeatability.

Cost-Effectiveness: For high-volume production, stamping is relatively cost-effective due to its efficiency.

Strength and Durability: The process can enhance the strength of the metal, making it suitable for critical automotive components.

Tooling Costs: Initial costs for dies and presses can be high.

Material Limitations: Not all metals are suitable for stamping, and some might require additional processing to achieve desired properties.

Stamping allows for the production of parts that are strong, lightweight, and precise, making it a preferred method in the automotive industry where quality and reliability are paramount.

We are professional auto parts manufacturer and have passed IATF 16949 certified, this enable us to meet qualily requirement in auto parts production.