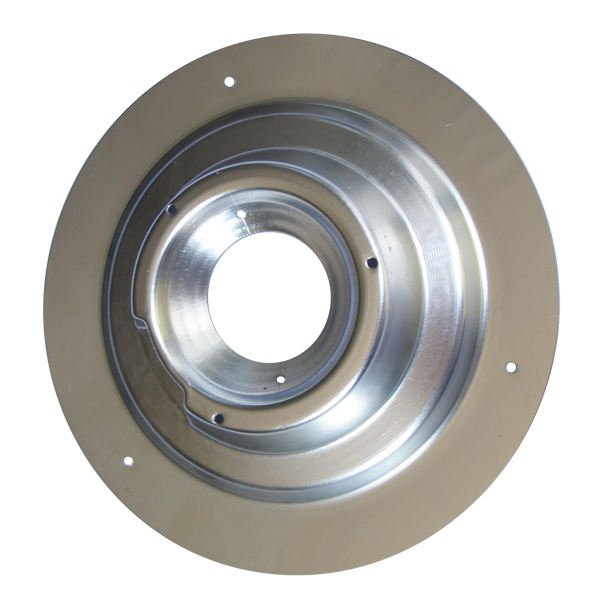

Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

Professional stamping parts factory, metal stamping parts factory, stamping part factory. Different tons of punching machines from 15T to 2000T can meet the production of any kinds metal stamping parts. IATF 16949 certified and Advanced testing equipments make us to ensure high quality products.

factory provide metal stamping fabrication, metal stamping and fabrication,progressive stamping and fabrication, metal forming stamping,metal stamping bending. progressive die completes all the forming processes of the product in one die, which overcomes the operation invariance and cumulative error caused by multiple positioning when using a simple die

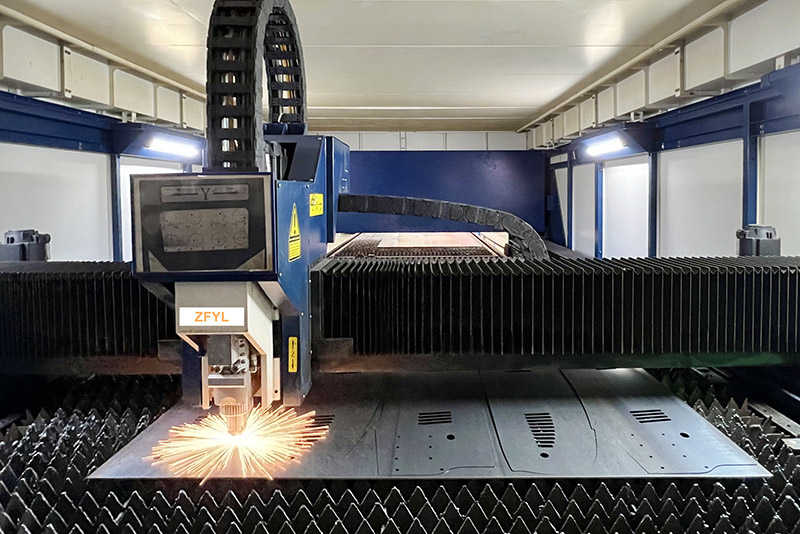

Custom Metal Laser Cutting Service

Metal laser cutting is a precise and efficient method used for cutting metal sheets and plates. It uses a high-powered laser beam to melt or vaporize the material, allowing for clean, intricate cuts with minimal distortion.

Stainless Steel: Excellent for its corrosion resistance and strength.

Aluminum: Lightweight and has good thermal conductivity.

Carbon Steel: Commonly used for its strength and durability.

Brass and Copper: Used for applications requiring high electrical conductivity.

Laser Generation: A laser cutting machine generates a laser beam using a laser source, often a fiber laser or CO2 laser.

Beam Focus: The laser beam is focused onto the metal surface through a series of mirrors and lenses.

Material Interaction: The concentrated laser beam heats the metal to the point where it melts or vaporizes. An assist gas, such as oxygen or nitrogen, is often blown through the cut to blow away the molten material and improve the cut quality.

Cut Path: The machine moves the laser beam along a programmed path to create the desired cut shape.

Precision: Capable of producing intricate and accurate cuts with tight tolerances.

Speed: Faster than traditional cutting methods, especially for complex designs.

Minimal Waste: The precision of the cuts reduces material wastage.

Versatility: Can cut through various thicknesses and types of metal.