Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

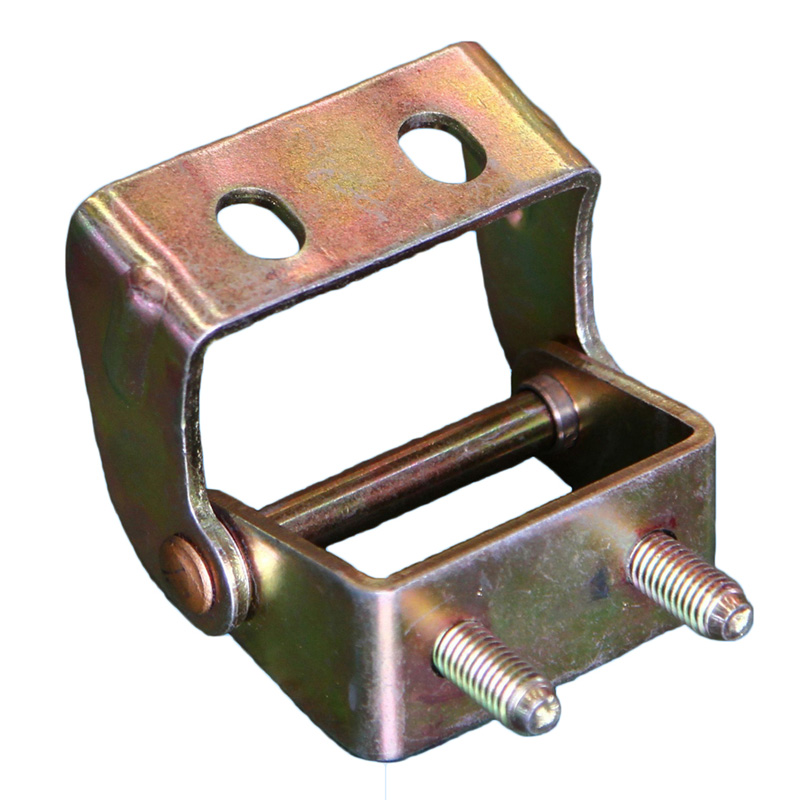

car door hinges, car hinge, car door hinge replacement, hinge car, car door hinges types. Use for car door or bus door, high quality and easy installation. Big volume in stock and fast shipping.

fabrication and welding, steel fabrication and welding, welding and metal fabrication. Black powder coating can meet over 96 hours of salt spray test,Good corrosion resistant.

Precision Industrial Metal Engineering Stamping

Engineering stamping typically refers to the process of using mechanical presses and dies to shape sheet metal into various forms and components. It's a crucial manufacturing method in industries such as automotive, aerospace, electronics, and appliance manufacturing. Stamping involves pressing or stamping a sheet of metal between dies to create the desired shape, which can range from simple flat parts to complex three-dimensional components.

Key aspects of engineering stamping include:

1. Dies and Tooling: Stamping dies are specialized tools that are custom-designed for each part to be stamped. They are made from hardened steel and consist of two main parts: the punch, which forms the part shape, and the die, which holds the sheet metal and provides the desired contours.

2. Material Considerations: The choice of material for stamping depends on the application requirements, including strength, ductility, and corrosion resistance. Common materials include steel, aluminum, copper, and various alloys.

3. Process Steps: The stamping process typically involves feeding a sheet of metal into a press, where it is clamped between the dies. The press then applies force to shape the metal according to the contours of the dies. This can involve multiple stages (progressive stamping) for complex parts.

4. Advantages: Engineering stamping offers several advantages, such as high speed production, accuracy, repeatability, and the ability to create complex shapes with tight tolerances. It is often more cost-effective for high-volume production compared to other methods like machining.

5. Applications: Stamped components are used in a wide range of products, including car bodies, electrical enclosures, household appliances, and consumer electronics. The ability to mass-produce parts with high precision makes stamping crucial in modern manufacturing.

Overall, engineering stamping is a versatile and efficient manufacturing process that plays a significant role in producing a variety of metal components used in everyday products and industrial applications.