Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

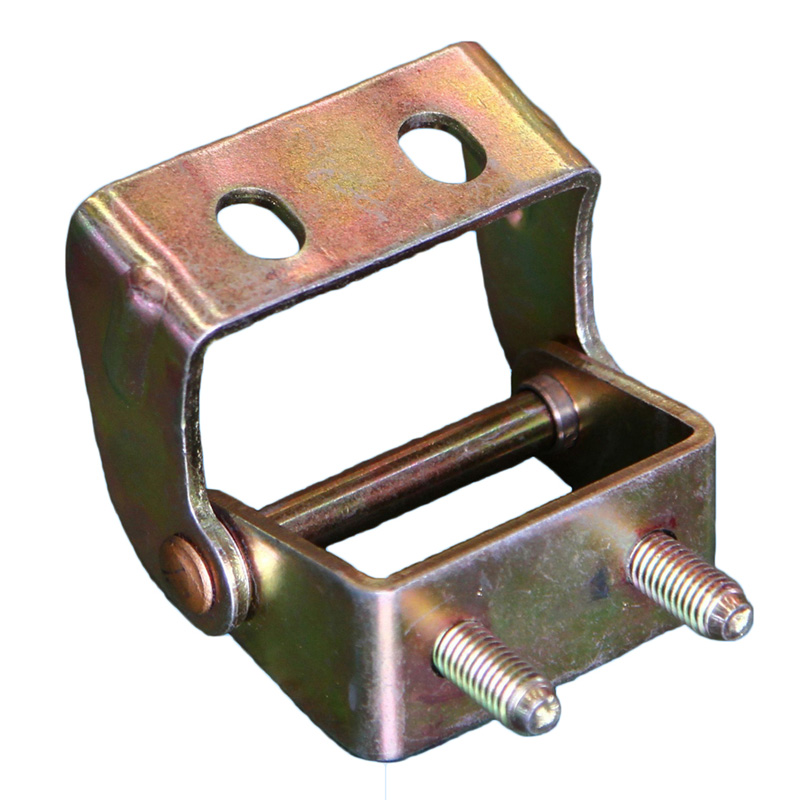

car door hinges, car hinge, car door hinge replacement, hinge car, car door hinges types. Use for car door or bus door, high quality and easy installation. Big volume in stock and fast shipping.

fabrication and welding, steel fabrication and welding, welding and metal fabrication. Black powder coating can meet over 96 hours of salt spray test,Good corrosion resistant.

Multi Slide Progressive Oem High Precision Stamping

Progressive stamping(stamping progressive), also known as progressive die stamping, is a manufacturing process used to produce parts or components from metal sheets. Progressive stamping is valued for its speed, precision, and ability to produce complex parts with minimal waste, making it a staple in modern manufacturing processes.

Multi-slide stamping, also known as four-slide stamping or multi-slide forming, is a specialized metal stamping process used to create intricate and complex parts from sheet metal or wire.

Multi-slide stamping offers advantages in terms of efficiency, precision, and versatility for manufacturing complex metal parts, making it a valuable process in modern industrial production.

High precision stamping refers to a manufacturing process where intricate parts are created from sheet metal using a stamping press. This process is known for its ability to produce parts with tight tolerances and complex geometries.

High precision stamping plays a critical role in modern manufacturing, enabling the production of intricate parts that meet strict quality standards and functional requirements.

OEM stamping (stamping oem) typically refers to the process of manufacturing parts or components for Original Equipment Manufacturers (OEMs).

This involves using stamping presses and dies to shape metal sheets or strips into desired forms or parts that meet the specifications provided by the OEM.

The process usually starts with a design provided by the OEM, which includes detailed drawings and specifications of the part to be stamped.

These designs are then used to create tooling and dies that will be used in the stamping process.

OEM stamping is common in industries such as automotive, aerospace, electronics, and appliances, where precision parts are needed in large quantities.

It allows OEMs to outsource the manufacturing of components while ensuring they meet their quality and performance standards.