Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

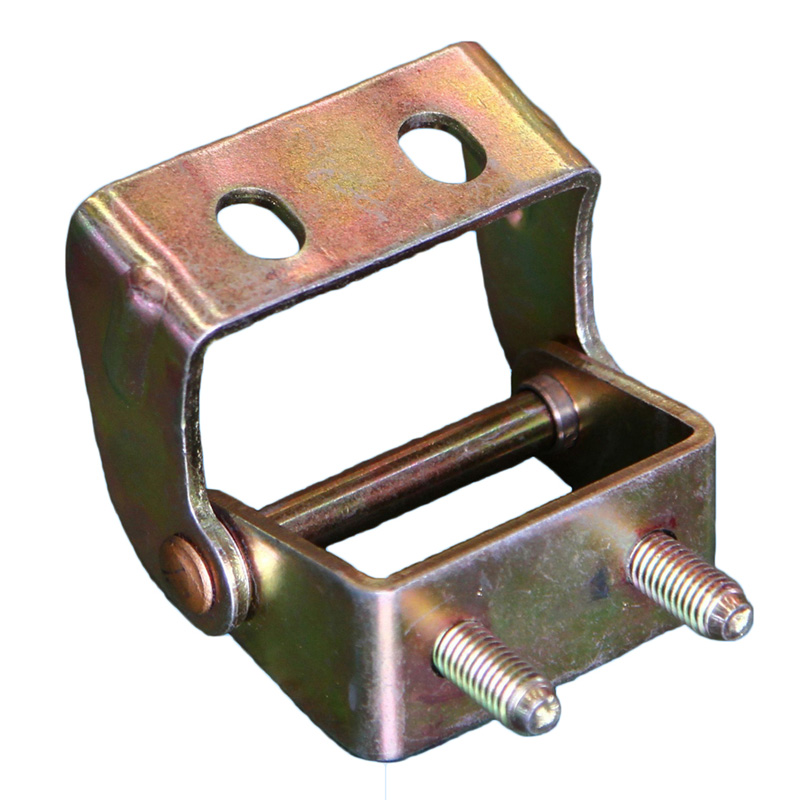

car door hinges, car hinge, car door hinge replacement, hinge car, car door hinges types. Use for car door or bus door, high quality and easy installation. Big volume in stock and fast shipping.

fabrication and welding, steel fabrication and welding, welding and metal fabrication. Black powder coating can meet over 96 hours of salt spray test,Good corrosion resistant.

Metal Stamping Base For Washers

washer stamping, .

Washer stamping typically refers to a manufacturing process where washers (flat, thin discs with a hole in the center) are produced using stamping machinery.

Stamping is a method of shaping metal by pressing it into a die to create the desired shape and size.

Washer stamping refers to the process of manufacturing washers using stamping techniques. Stamping is a method of forming a flat sheet of metal into a desired shape using a press and a die.

For washers, which are typically thin, flat, circular metal discs with a hole in the center, stamping is an efficient and cost-effective manufacturing method.

Here’s a brief overview of the washer stamping process:

1. Material Selection: Washers can be stamped from various metals such as steel, aluminum, brass, or stainless steel. The choice of material depends on factors like strength requirements, corrosion resistance, and cost.

2. Die Design: A die is a specialized tool used in stamping that shapes the metal into the desired washer form. The die consists of upper and lower halves that fit together and are mounted in a press.

3. Stamping Process:

- Blanking: A flat sheet of metal is fed into the stamping press. The press then cuts out round discs of metal, known as blanks, which will become the washers.

- Forming: The blanks are then transferred to another part of the die where they are stamped to form the final washer shape. This may involve pressing the washer against a die cavity to give it the desired thickness and shape.

- Hole Punching: During the stamping process, a punch also creates a hole in the center of each washer, which is critical for their function.

4. Finishing: After stamping, the washers may undergo additional processes such as deburring (removing sharp edges), cleaning, and coating (e.g., plating or painting) to enhance their properties or appearance.

5. Quality Control: Throughout the stamping process, quality control measures ensure that the washers meet specified dimensions, tolerances, and material requirements.

Washer stamping is preferred for its high speed, repeatability, and ability to produce large quantities of washers with consistent quality.

It is widely used in industries such as automotive, aerospace, electronics, and construction where washers are essential components in assembly and manufacturing processes.