Wholesale Cheap Replacement Aftermarket Car Parts

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

car parts, car parts wholesale, aftermarket car parts, auto car parts, replacement car parts. Quick customized on aftermarket car parts,just send us original samples or drawings.

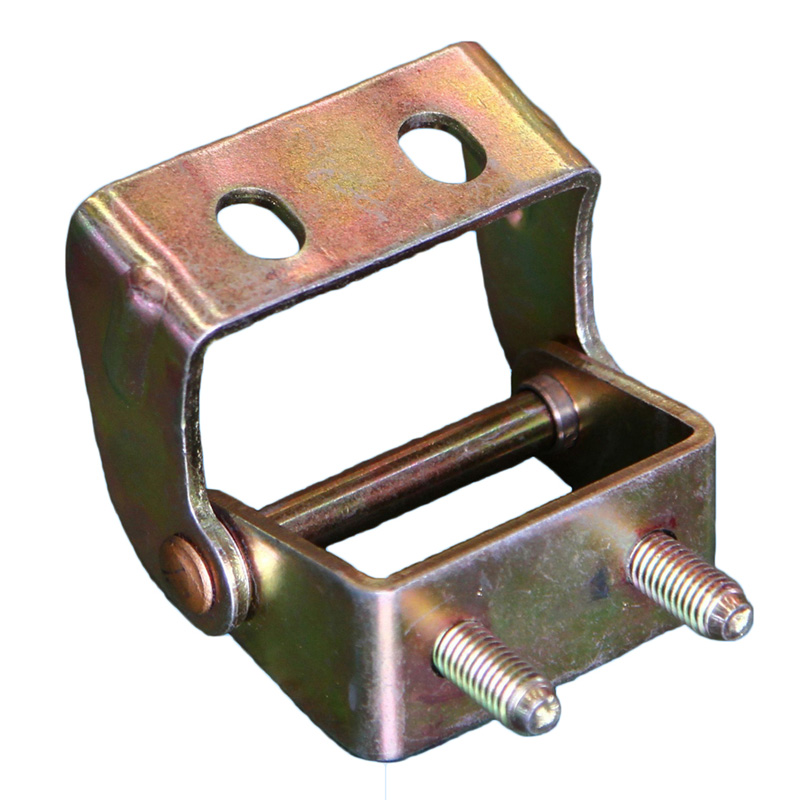

car door hinges, car hinge, car door hinge replacement, hinge car, car door hinges types. Use for car door or bus door, high quality and easy installation. Big volume in stock and fast shipping.

fabrication and welding, steel fabrication and welding, welding and metal fabrication. Black powder coating can meet over 96 hours of salt spray test,Good corrosion resistant.

High Speed Rapid Prototype Metal Stamping

Metal stamping is a manufacturing process used to create parts or components from metal sheets. We offer prototype metal stamping, rapid stamping, high speed metal stamping,rapid prototype stamping services. Here’s a brief overview of how it works:

1. Design and Prototype Development: Initially, engineers design the part and create a prototype. This prototype serves as a model for the final stamped part.

2. Tool and Die Creation: Tool and die makers then create the stamping die, which is a specialized tool that shapes and cuts the metal. The die is typically made from hardened steel and consists of two halves: the punch and the die.

3. Setup: The metal sheet, which can vary in thickness, is loaded into the stamping press. The press may be hydraulic, mechanical, or pneumatic, depending on the requirements of the job.

4. Stamping Process:

- Blanking: Involves cutting the outline of the part from the metal sheet, creating a flat piece known as a blank.

- Forming: The blank is then formed into the desired shape using the die. This can involve bending, drawing, stretching, or deep drawing, depending on the complexity of the part.

- Piercing: Holes or other features may be pierced or punched into the part as required.

5. Quality Control: Throughout the process, quality control measures ensure that each part meets specifications. This may involve dimensional checks, visual inspections, or other testing methods.

6. Finishing: After stamping, parts may undergo additional processes such as deburring (removing sharp edges), surface treatment (like painting or plating), or assembly if required.

7. Testing and Evaluation: Prototypes and initial runs are thoroughly tested to ensure they meet performance standards and can be mass-produced reliably.

Metal stamping is favored for its ability to produce large quantities of parts quickly and cost-effectively, making it suitable for various industries including automotive, aerospace, electronics, and more.